The Globe is the geographical projection of the earth on the scale of 1:10 000 000 realized in a handicraft way. The ball body with its diameter of 1.28 m has been stick get in a pivoted manner onto an axle which is – according to the inclined ecliptic – oblique by 23,5° towards the vertical.

In 1968, this sculpture was designed as a self-order of Manfred Küttner, an engineer, who lived in Leipzig at that time and who is a recognized artisan. This sculpture was then built in his “Workshop for Handicraft Metalworking” in Wernigerode. The artisan aimed at creating an aesthetically demanding object, allowing him to apply the fascinating transparent stud enamel technique to an object which is both impressive and timelessly valid, having a decorative effect and a practical value as well. Thus he decided on the glass-on-metal – world globe. Due to the fact that the artisan had been working on the Globe for 20 years, it became his “lifework”.

The surface of the Globe comprises 578 tiled segments, the form and size of which resulting from the single surfaces between every 10th degree of longitude and every 1oth degree of latitude. The two circular pole discs are penetrated by the earth’s axis.

Each of these segments is enamel work, finished in a furnace. They consist of arched copper plates, 1.2 mm in thickness, with transparent decorative enamel on their front side and counter-enamel on their back. The borders between the continents are shown by metal studs, melted into the enamel layer. The sea areas appear glazed in azure blue, the land areas from golden-yellow to golden brown in dependence on their altitude. Zones of everlasting ice are over-melted with opal white. Lakes and rivers had been etched into the copper plates prior to burning, and thus they are visible under the transparent enamel.

About 500 places of geographical significance are shown. Oceans and continents are marked with Roman antique letters. As metallic parts, protruding from the enamel, all writings and studs have been gold-plated after burning.

The hollow body of the ball, which the plates are attached to, is made of glass-fibre reinforced polyester. The wall thickness is some 20 mm. The plates, fixed by means of special adhesive, are separated by slits of 3 mm in width. These slits have been filled with anthracite-grey Portland cement and sealed with wax oil. Their striking appearance causes characteristic features of a globe.

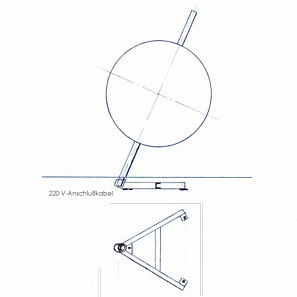

The ball is pivoted with 2 continuously greased ball bearings on a full floating steely axle. A separate chamber in the upper ball interior accommodates an electromechanical drive. A back-geared motor is flanged to the axle and transmits its driving power to the ball, the latter rotating on its axle once every 5 minutes. You can remove the upper pole disc in case you need access to the drive. Power supply is effected via cable through the hollow axle.

The Globe can be erected wherever it protected from precipitation. In any case, prevent free water from entering the slit between the axle and the rotating ball.

The Globe is located in such a height that an optimum view is possible. Its highest point is at 1.63 m, its lowest at o.36 m. Its inclined position meets the viewer’s demands. In the course of half a rotation, low parts are wandering higher, high pats lower.

The inclined axle, coated with high-grade steel sleeve, gets out of the ground directly on the erection site. The axle is located in a socket, the latter forming part of a three point bearing basis. This stand requires a ground recess of 15 cm in depth and 100 cm in width. After inserting the stand, fill the recess with customary coating.